Estrichaufbau – Lernen Sie Ihren Fußboden kennen

Estrich ist ein fugenloser, belastbarer und flexibel einsetzbarer Fußboden für Wohn-, Geschäfts- und Industrieflächen. Je nach Material, Versiegelung und Verlegung ist es möglich, mit dem Estrichaufbau verschieden Einsatzziele zu erreichen, zum Beispiel als Heizestrich, Gefälleestrich oder als Schutz vor aggressiven Chemikalien. Die Anpassung der Estrich-Aufbauhöhe erlaubt zudem einen präzisen Niveauausgleich.

Schicht für Schicht vom Rohbau bis zum Fertigfußboden

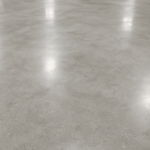

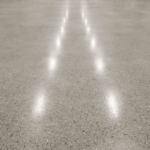

Die tragende Schicht für Ihren Fußboden bilden die Bodenplatten oder Geschossdecken Ihres Gebäudes. Der Rohfußboden ist oft uneben, rau und kann Belastungen nur schwer verteilen. Eine Deckschicht aus Estrich gleicht solche Unebenheiten aus. Diese Nutzschicht ist geeignet, um in Wohnräumen mit Parkett, Fliesen oder Teppich belegt zu werden. In Kellern, Garagen und modernen Lofts verbleibt der Estrich oft als ansehnlicher Nutz- oder Sichtestrich. Der Estrichaufbau sieht je nach Einsatzzweck eine Verlegung vor, die schwimmend, gleitend oder in festem Verbund mit dem Untergrund erfolgt. Der Fertigfußboden ist dann die Gesamtheit aus Rohdecke, Dämmung, Estrich und einem optionalen Bodenbelag.

Verbundestrich – für große Lasten und hohe Kraftübertragung

Um stärksten Dauerbelastungen standzuhalten, bietet der Verbundestrich die optimalen Voraussetzungen. Der Estrichaufbau besteht allein aus der Rohdecke, dem gewähltem Estrich und einem optionalen Belag. Für den Verbundestrich wählt Ihr Estrichleger einen Estrich mit ähnlichen Verformungseigenschaften zu der darunterliegenden Bodenplatte und achtet auf eine kräftige und dauerhafte Verbindung. So entsteht eine optimale Kraftübertragung über die gesamte Kontaktfläche.

Die typische Estrich-Aufbauhöhe ist recht schlank und beträgt nur etwa 20 mm für Gussasphaltestrich und etwa 25 bis 30 mm für Zementestrich. Verbundestrich bietet keinerlei Tritt- oder Schallschutz und wird daher vorwiegend für Industrieflächen, Tiefgaragen oder stark beanspruchte Keller eingesetzt.

Gleitestrich – stark für Keller und Terrassen

Sind die Lastanforderungen gering oder erlaubt der Untergrund keinen haftschlüssigen Verbund mit dem Estrich, dann bietet sich ein Gleitestrich an. Der Estrichaufbau besteht aus der Rohdecke, einer gleitfähigen Trennschicht, dem Estrich und einem optionalen Belag. Die ein- oder zweilagige Trennschicht aus kunststoffgetränktem Papier, Rohglasvlies oder dünner Polyethylenfolie verringert die Reibung mit dem Untergrund. So kann der Estrich bei Belastung durch die Gleitbewegung gefahrlos kleinere Verformungen und Bewegungen ausgleichen.

Da die Trennschicht kaum aufträgt, wird die Estrich-Aufbauhöhe überwiegend von der Dicke des Estrichs bestimmt. Die Mindestdicke für Gleitestrich nach DIN 18560 (Estriche im Bauwesen) beträgt 45 Millimeter für Zementestrich und 15 Millimeter für Kunstharzestrich. Gleitestrich bietet nur minimalen Schall- und Wärmeschutz und wird im Wohnungsbau vorwiegend für Kellerräume, Terrassen und Balkone genutzt.

Schwimmender Estrich – ideal für alle Wohnbereiche

Beim schwimmenden Estrich hat der verarbeitete Estrich an keiner Stelle Berührung mit der Rohdecke oder aufragenden Bauteilen. Der Estrichaufbau besteht aus der Rohdecke, einer von Sperrschichten gesäumten Dämmschicht, dem Estrich und einem Fußbodenbelag. Dehnungsfugen isolieren den schwimmenden Estrich von den Wänden und verhindert Schall- und Wärmebrücken. Dadurch gelingt bei dieser Verarbeitung eine sehr gute Wärme- und Trittschallisolierung.

Die Estrichdicke beträgt für Zementestrich etwa 40 bis 45 Millimeter. Zu der gesamten Estrich-Aufbauhöhe kommen noch die Dicke der Dämmung, des Fußbodenbelages und einer optionalen Fußbodenheizung hinzu. Dient der schwimmende Estrich als gleichmäßige Wärmeverteilung für eine Fußbodenheizung, sprechen Fachleute auch von einem Heizestrich.

Als Estrichleger unterstützen wir Sie mit Freude bei Ihrer Planung, der Auswahl geeigneter Estricharten und der Festlegung Ihrer Estrich-Aufbauhöhe für den Niveauausgleich. Gleiches gilt für die Auswahl geeigneter Dämmmaterialien. Teilen Sie diesen Artikel gerne mit befreundeten Bauherren, die sich ebenfalls über den Estrichaufbau informieren möchten.

Starten wir ein Projekt

Rufen Sie uns an oder schauen Sie jederzeit vorbei. Wir bemühen uns, alle Anfragen innerhalb von 24 Stunden an Werktagen zu beantworten.

Gerne beantworten wir Ihre Fragen.

UNSERE ADRESSE:

Augsburger Str. 20, 91781 Weißenburg