Milling screed Costs

In the world of modern construction, the quality of subfloor preparation is invaluable. In particular, the precise milling of screed forms the foundation for a floor covering that meets the highest standards in terms of appearance, functionality and durability. Our service packages are designed to offer you maximum flexibility and a transparent cost structure. This means you can be sure of choosing the ideal solution for your building project, with full cost control. As leading experts in screed milling, we are committed to providing you with a service that is tailored precisely to your individual needs.

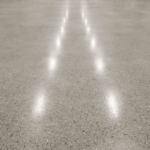

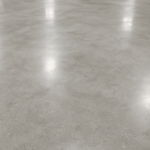

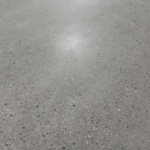

Screed milling according to thickness

Our screed milling services are finely tuned to the specific thickness of the screed to be worked on in order to ensure optimum preparation for the subsequent work steps:

Light milling (up to 5 mm): This option is ideal for removing minor irregularities or preparing the screed for a new surface coating. It ensures a smooth and even base, which is essential for the quality of the end product.

Deep milling (over 5 mm): For projects that require more extensive work on the screed - whether due to significant damage or to completely redesign the floor structure - this option is the right choice. With this method, even deeper layers of screed can be effectively removed and the substrate prepared for a new installation.

Extreme milling (over 10 mm): This category is intended for projects that require particularly intensive processing - for example, the removal of complete screed layers or preparation for a completely new subfloor. With specialized tools and techniques, we can meet even the most demanding requirements and optimally prepare the substrate for further work.

Your success is our goal

Our experienced team will support you with professional advice and conscientious execution of your screed milling work. By using advanced technologies and methods, we ensure precise and effective milling, regardless of the thickness of the screed. Our in-depth understanding of the materials and associated requirements ensures that your project is carried out with the utmost care and expertise to achieve first-class results.

Cost per square meter

from 300 m²

€ 25

per m²

- Arrival and departure

- Prepare work area

- Milling screed 2-3mm

- Remove building dust

- Disposing of screed fragments

- Clean foundation handed over