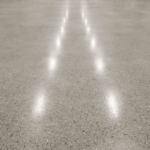

Synthetic resin screed (SR) - The high-performance solution for fast and special flooring requirements

Synthetic resin screed, standardized as SR (Synthetic Resin Screed) according to DIN EN 13813, represents the pinnacle of screed technology for demanding applications. Its exceptional properties such as extremely fast curing, high mechanical and chemical resistance and the possibility of low installation heights make it the ideal choice for industrial, commercial and time-critical renovation projects. As your specialist for modern screed systems, we offer comprehensive expertise in the planning and professional installation of synthetic resin screeds - one of our core competencies for floors that have to meet the highest standards.

Composition and material properties

The performance of a synthetic resin screed is determined by the precise interaction of its high-quality components. In contrast to mineral screeds, SR is based on a chemical reaction (polymerization) of synthetic resins. The main components are

- Binder: Reactive resins such as epoxy resin (EP), polyurethane resin (PUR), methyl methacrylate resin (PMMA) or unsaturated polyester resins (UP). The choice of resin type largely determines the properties of the screed (e.g. flexibility, chemical resistance, curing speed).

- Fillers/aggregate: Specially selected, dried quartz sand or other mineral fillers (in accordance with DIN EN 13139) with a defined grading curve to achieve the desired strength and surface structure.

- Hardener: A second component that is added to the resin in precise doses to start the chemical cross-linking reaction. The mixing ratio is critical and must be adhered to precisely.

- Additives (optional): Pigments for coloring, additives to improve workability, flow properties, UV stability, conductivity (for ESD floors) or to accelerate the reaction (especially at low temperatures).

Curing takes place via a chemical reaction that starts at room temperature and is extremely fast compared to cement screeds. The result is a very dense, low-porosity and highly resilient screed structure. Characteristic features include high compressive and flexural strength, excellent abrasion resistance, low layer thicknesses (often from just a few millimetres) and, depending on the resin type, high resistance to chemicals, oils and greases. Synthetic resin screeds are also inherently waterproof and low-shrinkage.

Wide range of applications

Synthetic resin screed as a robust screed is particularly suitable for:

- Industry: Production halls and warehouses, workshops with high mechanical loads (forklift traffic) and/or exposure to chemicals.

- Commercial: Highly frequented sales areas, commercial kitchens, cold stores - where load-bearing capacity, hygiene and rapid usability of the screed are crucial.

- Rapid renovation: When existing screeds or substrates need to be quickly reworked or leveled and only a short time window is available.

- Leveling: For leveling larger unevenness before laying final floor coverings or coatings.

- Special applications: As a substructure for special requirements such as ESD protection or in areas with strict hygiene regulations.

The decisive advantages of synthetic resin screed

Synthetic resin screed is a convincing screed solution:

- Extremely fast curing: screed can be walked on and loaded quickly, minimizes downtimes.

- 💪 Very high mechanical load-bearing capacity: Excellent compressive, flexural and abrasion resistance of the screed material.

- 🧪 E xcellent chemical resistance: The screed can withstand many aggressive substances (depending on the resin type).

- 📐 Efficient construction heights: Enables robust screed construction from a layer thickness of approx. 5-6 mm.

- 💧 Waterproof and hygienic: Forms a dense screed layer, ideal for wet areas and high hygiene standards.

- 🔗 Virtually shrinkage-free curing: Reduces the risk of stresses and cracking in the screed.

- 🌡️ Good thermal conductivity: Suitable for use as a heating screed on underfloor heating systems.

Technical properties and classification according to standard

Synthetic resin screeds are classified in accordance with DIN EN 13813. The designation SR-C[value]-F[value] provides information on the compressive (C) and flexural (F) tensile strength of the screed material. Other characteristic values can describe the wear resistance (A), the adhesive tensile strength (B) etc.

Overview of typical properties by resin type (for screed applications):

| Resin type | Type. Compressive strength (N/mm²) | Type. Bending tensile strength (N/mm²) | Main features as screed | Typical screed applications |

|---|---|---|---|---|

| Epoxy resin (EP) | 40 - 80+ | 15 - 30+ | Very high strength, good chemical resistance, for high loads | Industrial screeds, heavy-duty commercial surfaces, leveling layers, substrate for coatings |

| Polyurethane (PUR) | 30 - 60 | 10 - 25 | Tough-elastic, crack-bridging, comfortable, good sound insulation | Comfort screeds, renovation on vibrating substrates, under resilient floor coverings |

| PMMA | 35 - 60+ | 12 - 25+ | Extremely fast-curing, cold-elastic, good chemical resistance | Rapid refurbishment, cold storage screeds, repair mortar, industry under time pressure |

ℹ️ Note: The selection of a suitable synthetic resin screed system requires specialist knowledge and must be tailored to the specific project requirements (load, substrate, layer thickness, time frame).

Processing and the critical factor of curing time

The quality of the synthetic resin screed depends crucially on precise processing:

- Substrate inspection and preparation: Absolutely crucial. The substrate must be sound, dry, clean and suitably prepared (e.g. shot blasting, milling) and primed.

- Mixing: Strictly adhere to the mixing ratio of resin, hardener and fillers as specified by the manufacturer. Homogeneous mixing is essential. The pot life (working time) is limited.

- Application and spreading: Rapid application of the screed mortar to the target height using a smoothing trowel, squeegee or sword. Carefully compact and smooth the surface.

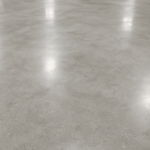

- Surface finish: The screed surface can remain smoothed or slightly roughened depending on requirements (e.g. as a substrate for other coverings).

- Hardening: The chemical reaction ensures that the screed hardens quickly.

The curing time is a significant advantage. The screed can often be walked on after just a few hours and is fully loadable after 1-7 days (depending on the system and temperature). CM measurement is not necessary.

⚠️ Compliance with the processing guidelines (temperature, humidity, mixing ratio) is essential for the quality and durability of the screed.

Design variants

Synthetic resin screeds are almost exclusively applied as bonded screeds, i.e. they form a strong adhesive bond with the prepared substrate. The typical structure comprises

- Primer: For sealing pores and promoting adhesion to the substrate.

- Synthetic resin screed layer: The actual screed layer in the planned thickness, consisting of the resin-filler mixture.

- Optional wear layer/sealer: If the screed is to be used directly, a thin resin sealer or a synthetic resin coating can be applied as a finish to improve cleanability or to achieve specific properties (color, slip resistance).

Our quality promise for your high-performance screed

The performance and durability of your synthetic resin screed are based on high-quality materials and perfect craftsmanship. We guarantee:

- System reliability: Use of tested screed systems from renowned manufacturers.

- Conformity to standards: Compliance with all relevant standards (DIN EN 13813, DIN 18560).

- Careful substrate preparation: As a foundation for a durable bond.

- Precision in mixing and installation: guaranteeing the material properties.

- Professional competence: Trained personnel with experience in the installation of synthetic resin screeds.

- Quality control: Monitoring of installation conditions and execution.

- Responsibility: Professional advice on selecting the optimum screed system.

You can rely on our expertise. We create robust, durable and functional synthetic resin screeds - tailored to your requirements.

Frequently asked questions (FAQ)

It is not "better" across the board, but designed for other, higher requirements. It is superior for extreme mechanical/chemical loads, jointlessness or speed, but is also significantly more expensive. Cement screed is sufficient for many standard applications.

With the right choice of system for the respective load and professional execution, synthetic resin screeds are very durable and often last 15-25 years or longer, even under intensive industrial use.

Yes, an epoxy resin screed (EP) in particular is an excellent, very robust, chemical-resistant and low-maintenance solution for private or commercial garage floors.

Yes, most synthetic resin screed systems are well suited for underfloor heating. They conduct heat efficiently and can often be laid over the pipes in relatively thin layers.

The costs are significantly higher than those of mineral screeds. The price per square meter depends heavily on the chosen resin system (EP is usually cheaper than PU or PMMA), the required layer thickness, the enormously important effort required for substrate preparation and the size of the area. Roughly calculate with costs from approx. 80-100 €/sqm upwards. A precise quotation is essential.