Mastic asphalt screed (AS): The jointless high-performance floor - fast, tight, durable

Mastic asphalt screed, classified as AS (Asphalt Screed) in accordance with DIN EN 13813, is a high-quality bitumen-based screed solution that is installed while hot. Its particular strengths lie in its immediate watertightness after cooling and its excellent sound-insulating properties, particularly with regard to impact sound. These features, combined with its rapid usability and durability, make it the preferred choice for comfort-oriented residential buildings, public buildings and demanding renovations. As an experienced specialist company for mastic asphalt work, we master the demanding processing of this material and provide you with a screed that sets standards in terms of impermeability, quietness and durability.

Composition and material properties

Mastic asphalt is a mixture of carefully selected components that is prepared and processed at high temperatures (approx. 220-250 °C):

- Binder: road bitumen (in accordance with DIN EN 12591) or special, e.g. polymer-modified bitumen (PmB), which gives the screed its viscosity, elasticity and impermeability.

- Aggregate: A graded mixture of sand, chippings and filler (stone powder) in accordance with DIN EN 13043. The precise grading curve is decisive for the impermeability and mechanical properties of the screed.

- Additives (optional): Polymers or other additives can be used to improve certain properties such as stability or processing at lower temperatures.

In contrast to cement or synthetic resin screeds, the hardening of mastic asphalt does not occur through a chemical reaction or hydration, but solely through physical cooling. As it cools, the bitumen forms a dense matrix that encloses the aggregate. The result is a low-cavity, watertight and tough-elastic screed structure. It is characterized by its high density, good thermal insulation compared to mineral screeds, excellent impact sound insulation and its dust-free properties when finished.

Wide range of applications

Due to its unique properties, mastic asphalt screed is suitable for a wide range of applications:

- Residential construction: Ideal as a floating screed for maximum living comfort thanks to impact sound and thermal insulation, especially in apartment buildings.

- Office and administration buildings: For quiet working environments and durable floor constructions.

- Public buildings: schools, hospitals, daycare centers benefit from the robustness, hygiene (dust-free, jointless) and sound insulation.

- Archives and storage: Waterproofness and dust-free conditions are often decisive criteria here.

- Renovation and old buildings: Does not introduce any additional building moisture, ideal for wooden beam ceilings or moisture-sensitive areas.

- Waterproofing layer: Can be used as the sole waterproofing layer or in combination with other systems, e.g. on parking decks (with special formulations).

- Substrate for various floor coverings: Suitable for tiles, parquet (fully bonded), carpet, linoleum and other coverings.

The decisive advantages of mastic asphalt screed

Mastic asphalt screed offers a convincing combination of advantages:

- 💧 Immediate waterproofness: The screed is waterproof immediately after cooling, no waiting times as with mineral systems.

- 🎧 O utstanding sound insulation: Offers excellent impact sound insulation values, which significantly increases living and working comfort.

- 🔥 Good thermal insulation properties: Contributes to energy efficiency and ensures a pleasant feeling underfoot.

- ⏱️ Fast usability: The screed can be walked on and loaded after just a few hours (after complete cooling).

- 💨 Dust-free & hygienic: The dense, abrasion-resistant surface is easy to clean and ideal for sensitive areas.

- Jointless installation: Can be laid over large areas without expansion joints in the screed field itself (edge joints are required).

- 🌱 S ustainable: Mastic asphalt is 100% recyclable and can be reused as a raw material.

- ⏳ Durable and robust: When professionally installed, it can withstand decades of use.

Technical properties and classification according to standard

Mastic asphalt screeds are classified according to DIN EN 13813. The marking is AS-C[value]-F[value]-IC[value]-A[value]:

- AS: Marking for mastic asphalt screed (Asphalt Screed)

- C[value]: Nominal compressive strength class in N/mm² (typically lower than for CT or SR, e.g. C12)

- F[value]: Nominal bending tensile strength class in N/mm² (e.g. F5)

- IC[value]: Indentation Class - This is a decisive characteristic value for mastic asphalt that describes its resistance to point loads (e.g. furniture feet). Common classes are IC10 (hard) to IC100 (very soft).

- A[value]: Wear resistance according to Böhme in cm³/50cm² (e.g. A15)

Overview of common indentation hardness classes (IC):

| Hardness class (IC according to DIN EN 13813) | Typical penetration depth* (mm) | Typical compressive strength C (N/mm²) | Typical bending tensile strength F (N/mm²) | Typical application examples |

|---|---|---|---|---|

| IC 10 | ≤ 1.0 | ~ C15 | ~ F7 | Industrial floors with high point loads, forklift traffic (special industrial asphalt) |

| IC 15 | ≤ 1.5 | ~ C12 | ~ F5 | Standard in residential construction, offices, schools, normal furnishings |

| IC 40 | ≤ 4.0 | ~ C7 | ~ F4 | Subordinate rooms, protective layers, not for direct use with point load |

| IC 100 | ≤ 10.0 | ~ C5 | ~ F3 | Pure sealing layers, soft protective layers |

*Maximum permissible penetration depth at defined test load and temperature. The C and F values given are typical examples and may vary depending on the formulation.

ℹ️ Note: The selection of the correct hardness class (IC) according to the expected use and load is essential for the suitability for use and durability of the mastic asphalt screed.

Processing and the cooling time factor

The processing of mastic asphalt requires special know-how and equipment:

- Substrate inspection and preparation: The substrate must be dry, clean and load-bearing. For floating installation, the insulation or separating layer is laid out.

- Heating and transportation: The mastic asphalt is heated to the processing temperature of approx. 220-250 °C in the asphalt boiler and transported hot to the installation site (often in insulated boilers or buckets).

- Application and spreading: The hot, flowable mastic asphalt is poured onto the substrate ("pouring") and spread evenly to the target height by experienced specialists ("asphalt pavers") using special wooden graters or screeds.

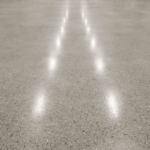

- Sanding the surface: Immediately after spreading, the still hot surface is sprinkled ("sanded") with fine, dried sand. This improves grip and appearance and can have a slight effect on the surface hardness.

- Cooling down: The screed must now cool down in a controlled manner. The duration depends on the layer thickness, the substrate and the ambient temperature, but is usually only a few hours. There is no drying time in the sense of water evaporation.

⚠️ Bitumen vapors are produced during processing, so ensure adequate ventilation. The high temperatures require strict occupational safety measures.

Design variants

Mastic asphalt screed is mainly laid as a floating screed on a suitable insulating layer (thermal and/or impact sound insulation) or on a separating layer. Edge insulation strips are essential for sound bridge-free separation from adjacent building components. A composite construction is not usual with mastic asphalt.

Our quality promise for your comfort floor

The unique advantages of mastic asphalt screed can only be fully exploited if it is laid professionally. Our work is based on uncompromising quality:

- Conformity with standards: Strict compliance with DIN 18560, DIN EN 13813 and relevant technical regulations.

- Material quality: Use of quality-controlled bitumen and aggregates.

- Specialist expertise: Use of experienced and trained asphalt pavers who have mastered the demanding hot processing.

- Precision: Careful temperature control, exact installation to target thickness and guarantee of evenness in accordance with DIN 18202.

- Care: Professional sanding and controlled cooling phase.

- Responsibility: Expert advice on choosing the right hardness class and the right structure.

Rely on our expertise in mastic asphalt construction. We create dense, quiet and durable screed surfaces for maximum comfort and value retention.

Frequently asked questions (FAQ)

Yes. Due to its dense, void-free structure created by the hot process, mastic asphalt is inherently watertight and is often used as part of structural waterproofing (e.g. on parking decks under other coverings).

Very quickly. As soon as the screed has cooled down to ambient temperature (usually after a few hours), it is usually fully loadable. There are no long drying times as with cement or calcium sulphate screeds.

No, mastic asphalt is not usually used for screeds over water-bearing plastic underfloor heating pipes due to its very high installation temperatures (approx. 230°C), as the pipes could be damaged. Mineral or synthetic resin screeds are the standard solution here.

The characteristic bitumen odor only occurs during hot processing and the cooling phase. After complete cooling and with normal ventilation, the odor is usually no longer perceptible.

The costs for mastic asphalt screed tend to be higher than for standard cement screed. This is due to the material costs for bitumen and aggregate and, in particular, the energy and labor-intensive, specialized hot processing with special equipment (stoves). A detailed quotation is required.