Floor coatings

- Home

- Floor coatings

Professional floor coating: protection, function & value for your surfaces

A floor is more than just a surface to walk or drive on - it is an integral part of the functionality, safety and aesthetics of a space or business. A professional floor coating is often the decisive measure to transform a simple substrate (such as concrete or screed) into a high-performance surface. It protects the substance, imparts specific properties and improves the appearance in the long term. As your nationwide partner for high-quality floor coatings, we offer you not only professional application, but above all the expertise to select and implement the optimum coating system for your requirements - for long-lasting results in industrial, commercial and demanding private areas.

Why a floor coating is often the best solution

A high-quality coating offers far more than a simple coat of paint:

- Sustainable protection & durability: It effectively protects the underlying screed or concrete from abrasion, impact, chemicals and moisture. This significantly extends the service life of the floor and reduces the need for renovation. Keyword: floor protection.

- Tailor-made functionality & safety: Depending on the system, surfaces can be designed to be non-slip (adjustable R classes), chemical-resistant, antistatic (ESD-capable) or particularly hygienic(seamless and non-porous). This increases occupational safety and meets specific industry requirements (e.g. HACCP).

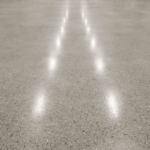

- Optimized care & appearance: Seamless floor coatings are much easier to clean and maintain than coverings with joints. In addition, the variety of colors and surface textures (matt, semi-gloss, glossy, with chips, etc.) enables an appealing design.

- Dust binding: Coatings bind the dust in the substrate and ensure clean conditions.

Expert insight: An investment in the right floor coating often pays for itself quickly through lower cleaning and maintenance costs and by avoiding damage and business interruptions.

Coating systems: Epoxy resin, PU & Co.

We work with various high-quality synthetic resin coatings to offer the best solution in each case:

- Epoxy resin coating (EP): The robust classic. Offers high hardness, compressive strength and good general chemical resistance. Ideal for industrial floor coating, warehouses, workshops or if you want to coat your garage floor.

- Polyurethane coating (PU): The flexible comfort floor. It is more elastic, therefore more comfortable to walk on, often sound-absorbing and better at bridging small cracks. Many PU systems are more UV-stable. Application: Sales areas, offices, but also suitable for balcony flooring.

- PMMA coating: The "sprinter". The main advantage is the extremely fast curing, even at low temperatures. Ideal for renovations under time pressure, e.g. in food processing plants or in the retail trade.

- (delimitation) Sealers: Thinner systems that are primarily used for dust protection and light consolidation, but offer significantly less protection and resilience than a real coating.

Expert tip: We make the choice between epoxy resin coating or PU coating (or PMMA) based on your specific use, the expected load and the ambient conditions.

Professional substrate preparation

The longevity of any floor coating stands and falls with the substrate! Inadequate preparation is the most common cause of later problems such as blistering or peeling. That is why we attach great importance to:

- Testing: Load-bearing capacity, cleanliness, evenness and above all residual moisture (CM measurement!) of the substrate.

- Cleaning: Removal of oil, grease, old coatings or dirt.

- Mechanical preparation: Sanding, shot blasting or milling to create a rough, stable and clean surface for optimum adhesion.

- Primer: Application of a primer matched to the system and the substrate.

Quality in execution: what we pay attention to

In addition to preparation, we guarantee professional application:

- Adherence to the correct mixing ratios and layer thicknesses.

- Careful workmanship, even on details such as connections and edges.

- Observe the processing and curing times.

Cost of a floor coating: a realistic estimate

The cost of a floor coating per square meter can vary greatly. Decisive factors are

- The selected system (EP, PU, PMMA) and the layer thickness.

- The condition of the substrate and the resulting preparation work (often a considerable cost factor!).

- The size and complexity of the area.

- Additional requirements (color, slip resistance, ESD, etc.).

A high-quality coating is an investment in the future of your surface. We will be happy to provide you with a transparent, detailed quote.

Your nationwide partner for durable floor coatings

Are you looking for an experienced floor coating company? We offer:

- Cross-system expertise: advice for EP, PU and PMMA systems.

- Focus on substrate preparation: Because we know that this is where quality begins.

- Trained specialists: For precise and clean workmanship.

- Reliability & adherence to deadlines: We work efficiently and predictably - nationwide.

Conclusion: Create added value with the right floor coating

A professional floor coating protects your floors, optimizes their function, increases safety and improves their appearance. It is a sustainable solution if it is professionally planned and implemented.

Project start: Advice for your floor coating

Whether it's coating a garage floor, renovating an industrial floor or renewing a balcony coating - we are your competent partner. Contact us for individual advice and a quote for your project anywhere in Germany! By phone, e-mail or WhatsApp.

Frequently asked questions (FAQ)

This depends on the use: Epoxy resin (EP) is harder and often more pressure-resistant, ideal for high mechanical loads (warehouse, workshop). Polyurethane (PU) is more flexible, more comfortable, often more UV-stable and better for bridging cracks or sound insulation (office, retail, balcony).

With professional workmanship and suitable maintenance, the service life depends heavily on the type of system, the coating thickness and the intensity of use. It can range from around 5-7 years for thinner systems under high loads to well over 15-20 years for high-quality, thicker coatings.

s there are DIY products. However, professional substrate preparation (sanding!) and the use of high-quality 2K systems by a specialist company are clearly recommended for a truly durable, well-bonded and visually appealing result. Mistakes during preparation often lead to rapid flaking.

The costs per square meter are very variable and depend heavily on the condition of the substrate (does it need to be prepared?), the size of the garage and the chosen system (simple sealing vs. thick EP coating). Always request an individual quotation for a reliable calculation.

A smooth coating can be slippery when wet. However, it can be specifically adjusted to be non-slip according to various R classes by means of special surface structures or the scattering of materials (e.g. quartz sand) in order to ensure occupational safety.