Underfloor heating milling system

- Home

- Underfloor heating

- Underfloor heating milling system

Underfloor heating in the milling system: retrofitting with minimum installation height

The integration of underfloor heating (UFH) in existing buildings often fails due to the limited available installation height. Removing the existing screed is often uneconomical or involves considerable effort. This is where the underfloor heating milling system offers a technically mature and efficient solution. This method enables a water-bearing underfloor heating system to be retrofitted by precisely milling channels directly into the existing screed. As your nationwide specialists for heating and screed systems, we have mastered this sophisticated technology and offer you professional planning and implementation for modern heating comfort, even in old buildings.

The milling system: Technical basics & how it works

The core principle of the milling system is the use of the existing screed as a support element for the heating pipes.

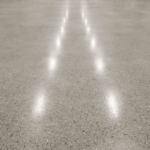

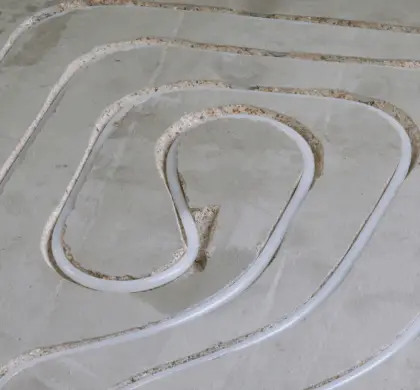

- Process: Using highly specialized screed cutters with integrated dust extraction, exact grooves (channels) are cut into the surface of the suitable existing screed according to a predefined installation plan.

- Integration: The system heating pipes are then inserted into these grooves. After a pressure test, the grooves are filled evenly with a suitable grouting or filling compound.

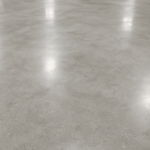

- The result: A thin-layer underfloor heating system with minimal installation height, as the pipes disappear into the screed construction and only the grouting compound (a few millimeters) and the new floor covering are added.

The installation process: precision from testing to backfilling

Professional implementation requires experience and precision at every step:

- Essential suitability test of the existing screed: This is the most critical step! We check in detail in advance:

- Screed type: Is it anhydrite screed (CAF), which is often very suitable, or cement screed (CT)?

- Thickness & load-bearing capacity: Is a sufficient residual thickness guaranteed after milling (usually at least 3-4 cm below the groove)? Is the screed firm and stable?

- Condition: Are there cracks or cavities? Are there installations in the milled area? Only a suitable screed allows screed milling for underfloor heating.

- Precision milling with dust extraction: Precise milling of ducts in accordance with heating circuit planning using powerful extraction systems to minimize dust.

- Installation of the system heating pipes: Professional insertion of the heating pipes suitable for the milling system (often dimensions 12-16 mm).

- Leak test: Mandatory pressure test of the installed pipe system in accordance with the manufacturer's specifications.

- Professional filling of the grooves: Use system-compliant, fast-setting grouting compounds for an even, stable surface.

Advantages of the milling system for renovation

This technology offers significant advantages for modernization:

- Minimized installation height: Allows a UFH to be retrofitted even where conventional systems fail due to the height. Existing door heights, stair connections, etc. usually remain unaffected.

- Fast heating response: The heating reacts very quickly to temperature changes due to the position of the pipes close to the surface.

- Preservation of the existing screed: Avoids the time-consuming, dirty and cost-intensive removal and disposal of the old screed as well as the long drying times of a new structure.

- Reduced installation time: Can often be realized much faster compared to new screed construction.

- Efficient heat dissipation: direct heat transfer to the floor covering and the room (less heat storage)

Technical requirements & planning principles

The success of the milling system stands and falls with the suitable existing screed. If this is not thick enough, unstable or made of unsuitable material, the process cannot be used. The planning of the heating circuits must also take into account the specific conditions and the fast reaction time. The thermal insulation beneath the existing screed also has a significant influence on the overall energy efficiency.

Cost-effectiveness of the milling system: costs in context

The costs for an underfloor heating milling system must be calculated on a project-specific basis. They depend on the area, the screed properties (hardness influences milling effort) and the complexity. Compared to the costs of a complete screed renovation with new construction, however, milling is generally the much more economical alternative for retrofitting a water-bearing underfloor heating system. A detailed quotation creates planning security.

Nationwide expertise for underfloor heating milling systems

As your specialist company, we offer:

- Thorough testing of the suitability of your existing screed for milling.

- Specialized technology for precise and low-dust screed milling.

- Experience in the planning and installation of thin-layer underfloor heating systems.

- Reliable execution and coordination - nationwide.

Conclusion: The milling system - a technically mature solution for retrofitting underfloor heating systems

If the conditions in the existing screed are met, the underfloor heating milling system is an excellent way of retrofitting modern heating comfort with minimum installation height. It is an efficient, time-saving and often more cost-effective alternative to a completely new floor construction during renovation.

Retrofitting thermal comfort? Ask for our expert advice!

Would you like to check whether the milling system is suitable for your property? Contact us for a professional assessment and a customized quote for retrofitting your underfloor heating. We are available nationwide - by phone, email or WhatsApp.

Frequently asked questions (FAQ)

There is no one-size-fits-all "best" system. In new buildings, the staple system and stud system are common and efficient. For retrofitting in old buildings with a low installation height, the milling system is often the ideal solution, provided the screed is suitable. We will advise you individually!

With the stapler system, the pipes are flexibly attached to an insulation board with pins. With the stud system, the pipes are pressed into fixed studs on a system panel, which speeds up installation and specifies the spacing.

No. The existing screed must be of sufficient thickness and stability and must not contain any critical installations. An on-site inspection by us or a specialist is essential.

As a full-service provider, we take on the detailed planning and design of the heating circuits to suit the room geometry and the calculated heat requirement in order to ensure optimum and even heat distribution.

Our offer usually includes: technical planning/design, delivery of the system (e.g. tacker or studded panels, heating pipes, manifolds), laying of the pipes including pressure test, delivery and installation of the coordinated heating screed (CT or CAF) as well as coordination/documentation of the heating protocol and CM measurement for readiness for covering.