Industrial screed

- Home

- Industrial screed

Industrial screed: Professional systems for the highest mechanical & chemical loads

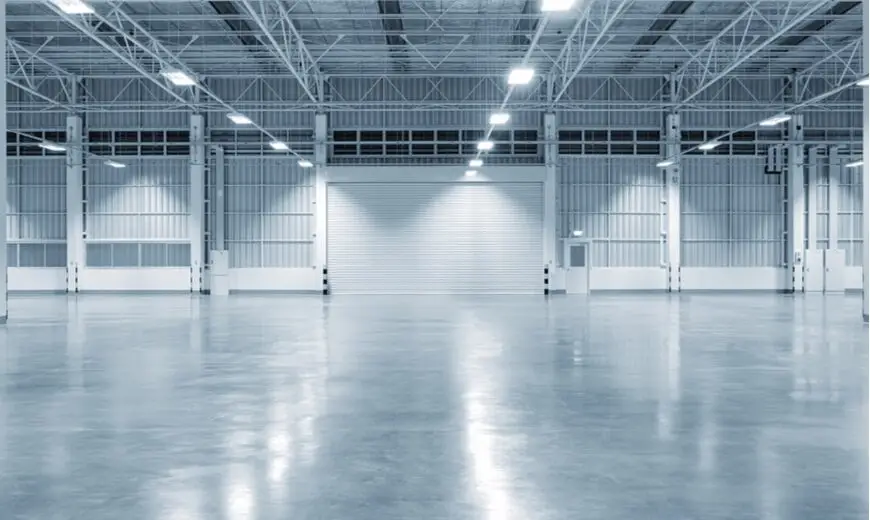

In industrial and commercial environments, the floor is one of the most heavily stressed components. It often has to withstand extreme loads that go far beyond what is usual in normal building construction. Where standard solutions fail, a specially designed industrial screed is essential. It forms the robust and durable foundation for safe and efficient operations. However, selecting the right system requires in-depth specialist knowledge of materials, loads and standards. As your nationwide partner for sophisticated flooring solutions, we specialize in the planning, selection and professional installation of industrial screed systems in accordance with DIN 18560 and DIN EN 13813, which are precisely tailored to the high requirements of your business.

Industrial screed: Requirements for high loads

A high-performance industrial floor begins with a precise analysis of the specific stresses. We check together with you:

- Mechanical resistance: Do you need a heavy-duty screed for forklift trucks, heavy machinery or high-bay warehouses? How high must the abrasion resistance be?

- Chemical resistance: Is the floor exposed to oils, greases, acids, alkalis or specific chemicals? A chemical-resistant screed is often mandatory here.

- Thermal loads: Are there extreme temperatures or are temperature shocks to be expected?

- Safety aspects: What slip resistance (R classes) is required? Is ESD discharge capability required?

- Hygiene and cleanability: Are seamless, non-porous surfaces necessary (e.g. for HACCP areas)?

- Flatness tolerances: Are there special requirements for flatness according to DIN 18202 (e.g. for automated storage systems)?

Expert insight: Only a detailed analysis of these factors leads to an industrial floor that works in the long term and is economical.

Industrial screed systems: Cement, synthetic resin, magnesite & mastic asphalt

We select the optimum screed system based on the requirements profile. We master the processing of various technologies:

- High-strength cement screeds (CT - e.g. CT-C35/F5 and higher):

- The robust basis: Mineral screeds ("cement screed industry") with high compressive strength, often fiber-reinforced, very resilient.

- Application: Often used as an economical base layer under a resistant top coat (e.g. epoxy resin) that provides surface protection. Requires drying time until ready for covering.

- Synthetic resin screeds (SR - EP, PU, PMMA):

- The high-performance specialists: systems based on epoxy, polyurethane or PMMA resins ("synthetic resin screed industry").

- Application: Offer maximum mechanical strength, excellent chemical resistance, are seamless (ideal for hygiene), extremely abrasion-resistant and can be used very quickly in some cases (PMMA). Often suitable as a direct wear layer.

- Magnesite screeds (MA):

- The special solution: Offer specific advantages such as electrical conductivity/antistatic and non-sparking (for EX areas!), oil-resistant.

- Use: Niche applications in potentially explosive atmospheres or special workshops. Sensitive to moisture.

- Mastic asphalt screeds (AS):

- The dense & robust: Hot installed, waterproof, absolutely dust-free, impact sound insulating, withstands high traffic loads.

- Application: Frequently used in parking garages, on ramps, in warehouses (including refurbishment) where impermeability or freedom from dust are important.

Expert tip: We always make the selection - whether CT, SR, MA or AS - based on the specific property and requirements. Careful consultation is crucial here.

Professional execution: Ensuring quality with industrial screed

The best system is useless without perfect workmanship. We guarantee:

- Professional substrate preparation: The substrate must be load-bearing, clean, dry and optimally prepared mechanically (e.g. shot blasting, milling, grinding) - this is the basis for any durable bond.

- Exact system structure: Compliance with all specifications for primer, mixing ratios, layer thicknesses and application techniques.

- Careful attention to detail: Professional execution of joints (for CT, AS), connections and edges.

- Controlled curing/post-treatment: Ensuring optimum conditions for strength development.

- Consistent conformity with standards: Strict compliance with DIN 18560, DIN EN 13813, DIN 18202 and other relevant technical regulations.

Industrial screed costs: an investment in longevity

The cost of industrial screed is an important consideration. Yes, they are higher than for standard screeds. This is due to the higher quality materials, the often complex substrate preparation and the specialized application. However, consider these prices per square meter as an investment: a professionally selected and installed industrial floor prevents costly repairs, reduces downtime and ensures a permanently safe and efficient working environment. We will be happy to provide you with a detailed quote after analyzing your project.

Your nationwide specialist for industrial screed

As an experienced company for industrial screed, we offer you decisive advantages:

- In-depth technical know-how: For all common industrial screed systems.

- Needs-based advice: We will find the optimum solution for your hall floor or workshop floor.

- Verifiable quality: Standard-compliant execution by experienced specialists.

- Reliable project management: We are your competent partner - nationwide.

Conclusion: Industrial screed - foundation for demanding industrial areas

A high-performance industrial screed is the technical basis for the functionality and cost-effectiveness of heavily used floors. The professional selection of a suitable system and precise execution to the highest quality standards guarantee long-lasting performance.

Your project start: Let us advise you!

Are you planning a new build or renovation with high demands on the floor? Contact us for expert advice and a customized quote for your industrial screed. You can reach us by phone or email - or simply send us your initial inquiry or photos of your project via WhatsApp. We are there for you nationwide!

Frequently asked questions (FAQ)

This depends on the exact load and frequency. A high-strength cement screed (min. CT-C35/F5) with a resistant epoxy resin coating is often a good solution. For extreme loads or exposure to chemicals, EP or PU synthetic resin screeds are the superior choice. A detailed analysis is necessary.

Yes, the initial investment is higher than for standard screeds. However, this is amortized by the significantly longer service life, lower maintenance and repair costs and avoided operational interruptions in demanding environments.

Yes, synthetic resin screeds are usually laid without joints, which is particularly advantageous for hygienic areas (food, pharmaceuticals). With cement, mastic asphalt and magnesite screeds, joints are usually unavoidable or necessary depending on the size of the area or system.

Chemical resistance is highly system-dependent. Synthetic resin screeds generally offer the highest performance here, which must be precisely matched to the media present. Magnesite screeds have good oil resistance. Cement and mastic asphalt screeds are only resistant to a limited extent without a special coating.

This varies greatly: PMMA synthetic resin screeds can be fully loaded after just a few hours. EP/PU synthetic resin screeds require several days. High-strength cement screeds must cure and dry for several weeks before they are fully loaded or can be coated (ready for covering!). Magnesite and mastic asphalt screeds also have specific curing/cooling times.