Calcium sulphate flowing screed (CAF): Ideal for underfloor heating & surfaces with few joints

Calcium sulphate flowing screed, classified as CAF (Calcium Sulphate Screed) in accordance with DIN EN 13813, is a highly developed screed solution that is characterized by its excellent self-levelling properties and particularly low shrinkage. These features enable the installation of large, joint-free surfaces with outstanding evenness - ideal for modern architecture and high-quality floor coverings. Its calcium sulphate base (anhydrite or alpha-hemihydrate) gives it specific advantages in terms of building biology and processing technology. As your experienced specialist company for screed systems, we guarantee expert planning and precise execution of calcium sulphate flowing screeds to meet the highest demands.

Calcium sulphate flowing screed in detail: the technology behind the flat floor

The key to the properties of calcium sulphate flowing screed lies in its binder - calcium sulphate (gypsum) - and special superplasticizers. Unlike cement, which shrinks as it hardens, gypsum crystallizes and largely retains its volume.

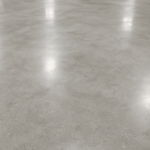

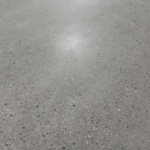

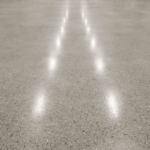

- Self-levelling for perfect evenness: Thanks to the superplasticizer, the CAF applied with pumps spreads almost automatically and forms a mirror-smooth surface - the ideal basis for any floor covering.

- Dimensionally stable for surfaces with few joints: The low shrinkage during curing is an enormous advantage. It allows us to create significantly larger areas with few joints or, depending on the geometry, even without joints (edge joints/connection joints may need to be taken into account) than would be possible with cement screed. This saves time when laying the flooring and ensures a harmonious appearance.

- Tested quality: We use factory premixed anhydrite screed to ensure consistently high material quality.

Composition and material properties

CAF is a mineral, factory premixed dry mortar whose quality and performance depend on the quality of its components and the exact formulation. The main components are

- Binder: High-quality calcium sulphate (CaSO₄) - either in the form of anhydrite (anhydrous) or alpha-hemihydrate. This binder is responsible for the strength development and the characteristically low shrinkage of the screed.

- Aggregate: Quality-tested sands (in accordance with DIN EN 13139) with an optimized grading curve, matched to the flowability and the desired grain structure.

- Mixing water: Added in a precisely defined quantity to control the flowability and enable crystallization of the calcium sulphate (gypsum formation). Compliance with the specified amount of water is crucial.

- Superplasticizer: Indispensable additives to achieve the self-levelling consistency with optimized water-binder value.

- Other additives/substances (optional): Used specifically to regulate processing time, flow behavior or to optimize specific properties (e.g. early strength).

Curing is based on the controlled crystallization of the calcium sulphate binder to form a dense gypsum structure (CaSO₄ - 2H₂O). Outstanding features are the very low shrinkage and swelling behavior, which enables the realization of large surfaces without or with only a few expansion joints (depending on geometry and heating). CAF is dimensionally stable after drying out and achieves high strengths. However, it is fundamentally sensitive to moisture and must not be exposed to permanent moisture penetration.

Areas of application for calcium sulphate flowing screed

Thanks to its properties, CAF is ideal for many interior applications:

- Residential construction: Ideal for single and multi-family homes, offers a high level of comfort and perfect evenness, especially under sensitive coverings such as parquet or large-format tiles.

- Office and administration buildings: Efficient installation in large areas, creates flat substrates for flexible room use.

- Public buildings: schools, hospitals, museums - wherever durability, evenness and, if necessary, building biology aspects are important.

- Heated floor constructions: As a heating screed, CAF enables excellent, cavity-free enclosure of the heating pipes and therefore very efficient heat transfer from underfloor heating systems.

- Renovation and old buildings: Well suited for leveling uneven substrates or with limited installation heights (depending on product and statics).

- Substrate for sensitive coverings: Its high evenness and dimensional stability make it ideal for parquet, designer flooring, linoleum and large-format tiles.

Important restriction: CAF is not suitable for areas permanently exposed to moisture, such as outdoor areas, washrooms, commercial kitchens or wet rooms with floor drains, unless special, complex and standard-compliant bonded waterproofing systems are planned and implemented. However, standard bathrooms in residential buildings are usually possible with professional waterproofing under the floor coverings.

Decisive advantages of calcium sulphate flowing screed

- 📐 Excellent evenness: Self-leveling properties make it easy to achieve the highest evenness tolerances in accordance with DIN 18202.

- ↔️ Minimum shrinkage: Enables the formation of large, jointless or jointless fields (up to several 100 m² without heating, approx. 300 m² with heating, depending on geometry and manufacturer's specifications), reduces the risk of cupping.

- 🚀 High installation performance: Fast installation thanks to pumpability and self-leveling, saves time and costs.

- 🌡️ Optimum thermal conductivity: Very good suitability as a heating screed due to complete pipe sheathing and good thermal conductivity.

- Building biology benefits: gypsum is a natural building material, CAF is low-emission and often pH-neutral, which can have a positive effect on the indoor climate.

- 💪 High strengths: Reliably achieves the planned compressive and flexural tensile strengths.

- ⏳ Early walkability/strength: Often walkable after 1-3 days and partially loadable after a few days (depending on product and conditions). However, readiness for covering takes time!

Technical properties and classification according to DIN EN 13813

The performance of a Calcium sulphate flowing screed is classified by its compressive (C) and flexural (F) tensile strength in the same way as cement screeds: CAF-C[Wert]-F[Wert].

- CAF: Calcium Sulfate Screed (calcium sulfate screed, here as a flowing screed)

- C[value]: Characteristic value of the compressive strength class (e.g. C25 for ≥25N/mm2)

- F[value]: Characteristic value of the bending tensile strength class (e.g. F5 for ≥5N/mm2)

The strength class is selected according to the structural requirements and the planned use.

Overview of common strength classes:

| Screed class | Minimum compressive strength (N/mm2) | Minimum bending tensile strength (N/mm2) | Typical application examples |

|---|---|---|---|

| CAF-C20-F4 | 20 | 4 | Residential construction (usual load) |

| CAF-C25-F5 | 25 | 5 | Residential construction, offices, public areas (standard) |

| CAF-C30-F5 | 30 | 5 | Areas with higher loads, light commercial areas |

| CAF-C35-F6 | 35 | 6 | Commercial areas with medium load |

| Higher classes | as required | as required | Specific requirements, higher point loads |

ℹ️ Note: The correct determination of the screed class is decisive for durability and function. It is carried out by qualified planners or the specialist company.

Processing and critical drying phase

The quality of the CAF depends crucially on careful processing and drying:

- Substrate inspection and preparation: cleanliness, dryness, impermeability (no holes in the separating layer/insulation!), professional installation of the edge insulation strips.

- Mixing: Strict adherence to the specified water quantity (check by means of a spreading dimension test on the construction site) in the continuous or compulsory mixer.

- Pumping and application: Continuous pumping of the liquid mortar onto the prepared surface.

- Spreading and leveling: Spread evenly to the target height using a buffing rod or squeegee. The material levels itself automatically.

- Protection from draughts: Freshly applied CAF must be protected from draughts to prevent surface cracks.

- Controlled drying: The drying time until the Readiness for covering is crucial and must never be underestimated ❌. It depends on:

- Screed thickness (decisive!)

- Umgebungsklima (Temperatur >5°C, rel. Luftfeuchte ideal < 65%)

- Effective air exchange (shock ventilation, no permanent draughts!)

- Specific product formulation

Rules of thumb are unreliable! ⚠️ Approval for covering may only be given once the material-specific required residual moisture has been reached. This is only reliably determined by CM moisture measurement (observe limit values, usually ≤0,5 CM-% for unheated, ≤0,3 CM-% for heated screeds - check manufacturer's instructions!) Premature laying on excessively damp CAF will inevitably lead to serious damage (detachment of covering, mold, destruction of screed structure). Surface preparation: Before laying floor coverings, it is often necessary to sand the surface of CAF to remove fine accumulations or a sintered layer and to ensure optimum adhesion for adhesives and primers.

Construction variants for calcium sulphate flowing screed

Due to its properties, CAF is mainly used as:

- Floating screed (screed on insulation layer): Standard application for optimum thermal and impact sound insulation.

- Heating screed: As a floating screed to accommodate and efficiently enclose underfloor heating pipes.

- Screed on separating layer: Allows movement relative to the substrate.

- Bonded screed: Rarer, requires special bonding bridges and the most careful substrate preparation.

- Fast screed variants: Also available as CAF, for accelerated drying and earlier readiness for covering (special formulations).

Professional execution - our quality promise

The longevity and function of your calcium sulphate flowing screed depend directly on a professional finish. Our quality standards include:

- Strict adherence to standards and regulations: DIN 18560, DIN EN 13813, BEB data sheets specifically for CAF.

- Tested system components: Use of high-quality, quality-monitored ready-mixed dry mortar and accessories.

- Precise application technique: correct water metering (spreading dimension), professional pumping and leveling.

- Ensuring evenness: compliance with tolerances in accordance with DIN 18202.

- Controlled drying conditions: Advice on correct ventilation, protection against moisture ingress.

- Responsible CM measurement: Reliable determination of readiness for covering before approval.

- Professional sanding: If necessary, for optimum preparation for the floor covering.

Rely on our expertise as a specialist company to perfectly implement the specific requirements of calcium sulphate flowing screed - for a floor structure that combines comfort, precision and durability.

Frequently asked questions (FAQ)

Only in domestic bathrooms and only with a verifiably perfect bonded waterproofing (in accordance with DIN 18534) directly under the tiles. Special care is required due to its sensitivity to moisture. It is unsuitable for commercial wet rooms.

The screed drying time until it is ready for covering (residual moisture ≤ 0.5 or ≤ 0.3 CM%) can take weeks to months and is often no shorter than with cement screed, as the limit values are lower! Regular ventilation and a CM measurement are crucial.

The costs are often comparable to cement flowscreed. Compared to conventional cement screed, material costs may be slightly higher, but this is often offset by the speed of installation. An individual quotation is required to clarify the costs.

Yes, this is usually necessary. Sanding removes a superficial layer of sinter and prepares the surface to receive the primer, which ensures adhesion of the covering or adhesive.

The excellent pipe perimeter ensures very good heat transfer. The low shrinkage reduces stresses during heating, and the first functional heating to support drying can often take place earlier than with cement screed.