Laying dry screed Costs

In today's construction industry, the efficiency of floor design is of crucial importance. A key element in this is choosing the right screed that not only meets technical and functional requirements, but also satisfies ecological and economic criteria. Dry screed systems offer an outstanding solution here. They combine numerous advantages, including quick installation, excellent insulating properties and a wide range of possible applications. As your reliable partner, we have made it our mission to find and implement the optimum dry screed solution for your project. Our expertise covers various materials and systems that are specially tailored to the individual requirements of your construction project. Below we present our carefully selected dry screed variants, which focus on both sustainability and performance. You will then find a transparent cost overview to help you make an informed decision.

Our dry screed solutions

Wood fiberboard - excellence in sustainability: Our range of wood fiberboards stands for environmental protection and outstanding acoustic insulation performance. This option is specifically designed for projects where sustainable building materials and a healthy indoor environment are a priority. With their natural nature, our wood fiber boards effectively contribute to improved indoor quality and responsible use of resources.

Mineral wool - The epitome of comfort and insulation: The mineral wool variant is the result of our efforts to deliver outstanding thermal and acoustic insulation properties. It is ideal for environments that demand maximum comfort and safety. Its robust insulating properties make it an ideal choice for demanding living and working areas where well-being and efficiency are paramount.

Rigid polystyrene foam - Economical and effective: Our rigid polystyrene foam panels represent a cost-effective solution that does not compromise on quality. They offer solid performance in terms of thermal insulation and are particularly popular due to their ease of handling. This option is recommended for projects that require excellent value for money without compromising on insulation quality.

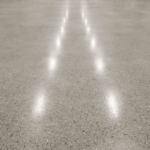

Precast screed - speed and efficiency: Our prefabricated screed is the ideal solution for projects with a tight schedule. It allows construction work to continue quickly thanks to its immediate load-bearing capacity after installation. This option is perfect for quick renovations and new builds where time is a critical factor.

Why lay dry screed?

Dry screed is not only a time- and cost-efficient solution for floor coverings, but also impresses with its versatility and performance in a wide variety of construction projects, especially in loft conversions and in situations where weight reduction is essential:

Time-saving installation: The quick and uncomplicated installation enables work to continue immediately, thus considerably reducing the construction time.

Ideal for loft conversions: Its lightness makes dry screed particularly suitable for loft conversions where the static load plays a critical role.

Weight-optimized: Due to its low weight, dry screed relieves the overall structure of the building, which is a great advantage, particularly in the case of renovations and extensions.

High adaptability: Whether sound or thermal insulation - dry screed offers a suitable solution for almost every requirement.

Sustainability: Many dry screed materials are environmentally friendly, support a healthy indoor climate and contribute to sustainable construction.

In short, dry screed is the ideal choice for projects where efficiency, adaptability and sustainability are paramount - be it a sophisticated loft conversion or the modernization of existing structures.

Prefabricated screed

without insulation

€ 45

per m²

- Arrival and departure

- Prepare work area

- Precise cutting of the panels

- Laying prefabricated screed

- Bonding & screwing panels

- Disposal of cutting waste

- Quality control and handover