Substrate preparation

- Home

- Substrate preparation

Substrate preparation for screed and concrete surfaces

The quality and durability of floor coatings, coverings or waterproofing depends on the quality of the substrate. Professional substrate preparation is therefore not an optional step, but an essential necessity in modern construction, especially when it comes to preparing concrete or screed. It creates the defined basis on which subsequent systems can adhere securely and reliably fulfill their function for years to come. Processes such as milling, grinding and shot blasting are established mechanical substrate preparation methods for optimally preparing substrates such as concrete, screed or asphalt for the application of new layers. This article sheds light on the technical aspects of these substrate renovation methods and their importance for architects and building owners who value the highest quality of workmanship and solid preparation for floor coatings.

Method of mechanical substrate preparation

The selection of the appropriate method for substrate preparation depends on the type of substrate, its condition, the layers to be removed and the requirements of the subsequent system.

Milling: Efficient removal and profiling of the substrate

- Principle: Subsoil milling involves the substantial removal of material by rotating milling drums fitted with carbide or diamond tools (milling blades). The penetration depth and thus the material removal can be precisely adjusted.

- Procedure: The milling machine is systematically guided over the surface to be machined. Depending on the machine size and tooling, different milling patterns and removal rates can be achieved. A powerful extraction system is essential to collect the dust and milled material directly.

- Areas of application: Removal of thick old coatings (e.g. epoxy resin, PU), damaged screed layers, adhesive residues or fillers; removal of excess height and unevenness; creation of grooves or defined profiles. The result is a highly roughened, profiled surface - an intensive form of substrate preparation.

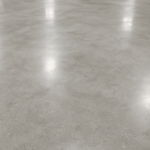

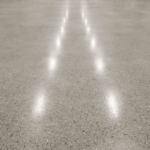

Sanding: Smoothing and fine preparation of substrates

- Principle: Surface sanding uses rotating sanding discs with diamond or PCD (polycrystalline diamond) segments. Removal is abrasive, whereby the roughness of the result is controlled by the grain size of the diamond segments. Ideal for grinding concrete or screed.

- Process: Sanding machines are guided over the substrate in strips. A distinction is made between dry and wet sanding. Modern machines also have an efficient dust extraction system. By changing the grain size, it is possible to switch from coarse to fine sanding.

- Areas of application: Smoothing concrete and screed surfaces; removing thinner coatings, paint markings, sintered layers or adhesive residue; grinding and sanding uneven areas; preparing for thin-layer coatings or exposed screeds (terrazzo look). The result tends to be a smoother, but defined, open surface depending on the grain size.

Shot blasting: Optimum surface roughness for concrete and screed

- Principle: In shot blasting, small steel balls (blasting media) are propelled onto the surface at high speed using a blasting wheel. On impact, they remove loose particles, dirt and the top layer of fine mortar (cement skin) and create a defined surface roughness.

- Procedure: The shot blasting machine moves over the surface. The abrasive is circulated: It is thrown on, bounces up, is sucked up together with the removed material, separated from the dust and fed back into the process. This enables virtually dust-free floor preparation.

- Areas of application: Primary preparation of concrete and screed surfaces before applying coatings (EP, PU), sealants or fillers; removal of cement skin (laitance), fine unevenness, dirt and old paint markings; roughening of smooth surfaces to improve grip. The result is a very clean, evenly roughened surface with an optimum adhesion profile - essential for adhesive tensile strength.

Advantages of substrate preparation

Professional mechanical substrate preparation offers decisive technical and economic advantages for your construction project:

- Maximum adhesive tensile strength: By removing non-load-bearing layers (e.g. cement skin, old coatings, soiling) and creating a defined surface roughness (increasing the surface area), the adhesion of subsequent systems is significantly improved. This is a basic prerequisite for their longevity and prevents delamination.

- Ensuring evenness: Milling and sanding in particular enable the correction of unevenness in accordance with the tolerance specifications (e.g. in accordance with DIN 18202). This is critical for the installation of large-format tiles, parquet or the application of self-leveling coatings.

- Defined surface quality: Depending on the requirements of the subsequent trades, the roughness (roughness depth) and open porosity of the substrate can be specifically adjusted in order to create optimum bonding conditions for the floor coating preparation.

- Efficiency and process reliability: Compared to manual methods, mechanical methods are often faster and lead to reproducible, homogeneous results over large areas. This minimizes the risk of defects and subsequent complaints during substrate restoration.

- Removal of harmful substances: Contamination or unsuitable old materials are safely removed, ensuring compatibility with the new system and preventing potential chemical reactions.

Quality assurance through professional preparation

Mechanical substrate preparation by milling, grinding and shot blasting is an indispensable part of quality-oriented construction projects. It creates the technical basis for the durable function and aesthetics of floor coverings and coatings. For architects and building owners, investing in professional floor preparation means ensuring construction quality, minimizing risks and ultimately guaranteeing the longevity of the entire structure. The choice of the right process and its professional execution are decisive for success.

Your partner for professional substrate preparation

Are you planning a project and need technically perfect substrate preparation in [optional: your region/city]? We will be happy to provide you with comprehensive advice on the best methods - milling, grinding or shot blasting - for your specific requirements. From the analysis of the existing substrate to the precise execution of the preparation work on concrete and screed. Contact us for a no-obligation consultation or a detailed quote.

Frequently asked questions (FAQ)

Milling: Heavy stock removal. Grinding: Smoothing, fine preparation. Shot blasting: Concrete/screed preparation (optimum adhesion). Exact choice after object inspection.

Ensures adhesion, evenness and durability of the new flooring/coating. Prevents expensive consequential damage.

Modern machines with powerful extraction minimize dust. Shot blasting is virtually dust-free.

Depending on area, process and condition. Exact time after project review.