Hard aggregate screed (industrial screed): The extremely resilient floor for industry & trade

Hard aggregate screed, often referred to as industrial screed and defined in accordance with DIN 18560-7 for heavy-duty screeds, is the ultimate solution when maximum mechanical load-bearing capacity and outstanding wear resistance are required. This special cementitious screed (CT) is based on the requirements of DIN EN 13813 and is specifically reinforced by the addition of hard materials in accordance with DIN 1100. The result is an industrial floor that can withstand even the most intensive forklift traffic, high point loads and heavy abrasion for decades. Ideal for production halls, logistics centers, workshops and garages - wherever a standard screed is not sufficient. As your specialist company for screed laying, especially for heavy-duty hard aggregate screeds, we offer you tailor-made, extremely durable and functional flooring solutions.

Composition and material properties

The exceptional performance of the hard aggregate screed is based on an optimized formulation that goes beyond that of a standard cement screed:

- Binder: High-quality cement (in accordance with DIN EN 197-1) as the basis for strength development.

- Aggregate: Selected sand/gravel (according to DIN EN 12620) with optimized grading curve.

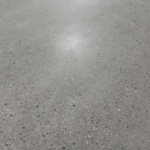

- Hard materials (according to DIN 1100): The decisive factor for robustness. Special mineral or metallic aggregates (classified in groups A, M, KS such as corundum, silicon carbide) are either mixed into the ready-mixed dry mortar or applied to the fresh screed as a hard aggregate to create a highly wear-resistant surface.

- Mixing water: Precisely dosed for optimum hydration and processing.

- Additives (optional): For fine-tuning properties such as workability, hardening speed or chemical resistance.

This composition results in a cementitious screed (CT) with significantly improved compressive strength (C), flexural strength (F) and extremely high wear resistance (A). The surface hardness and abrasion resistance are the outstanding features. Once fully cured, the screed is also insensitive to moisture and temperature-resistant.

Wide range of applications: Where robustness counts

Hard aggregate screed is the first choice for floors that are exposed to extreme mechanical stresses:

- Industrial halls & production facilities: Ideal as industrial flooring under heavy machinery and for intensive internal traffic.

- Warehouses & logistics centers: Perfect as a floor for logistics with intensive heavy load traffic from forklift trucks and pallet trucks.

- Workshops: As a robust workshop floor in car workshops, locksmiths or metalworking companies.

- Underground garages & parking garages: As a wear-resistant garage floor, especially on lanes and ramps.

- Loading zones & handling areas: Where high impact and point loads occur.

- Special applications: Also suitable for floors with specific requirements such as increased slip resistance, electrical conductivity or resistance to chemicals.

The decisive advantages of hard aggregate screed at a glance

Investing in a hard aggregate screed offers lasting benefits:

- 💪 Extreme wear resistance: Maximum abrasion resistance (high A class) for areas with intensive rolling and grinding wear.

- 🏋️ Highest load-bearing capacity: Excellent compressive and flexural tensile strength to absorb high static loads and dynamic stresses caused by heavy goods traffic.

- ⏳ Exceptional durability: A long-lasting flooring solution designed for decades of use with minimal wear.

- 💧 Moisture resistance: Insensitive to moisture after curing.

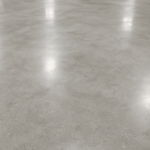

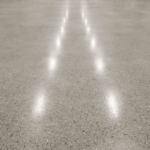

- 🔧 Perfect surface quality: Enables very even floors (in accordance with DIN 18202), which can often be used directly or form an ideal base for coatings.

- 💶 O utstanding cost-effectiveness: Despite higher initial costs, the long service life and low maintenance costs result in low life cycle costs.

- 🛡️ Mechanical robustness: High resistance to impacts, knocks and chipping.

- 🔥 Optimum fire protection: non-combustible, building material class A1 according to DIN 4102.

Technical properties & classification according to DIN EN 13813 / DIN 18560-7

The performance of highly stressable screeds is precisely defined. The classification for hard aggregate screed is: CT-C[value]-F[value]-A[value].

- CT: Cementitious screed.

- C[value]: Compressive strength class in N/mm² (e.g. C60 for ≥ 60 N/mm²).

- F[value]: Bending tensile strength class in N/mm² (e.g. F10 for ≥ 10 N/mm²).

- A[value]: Wear resistance class according to Böhme (cm³/50cm²). The lower the value, the higher the wear resistance (e.g. A6, A3, A1.5). The decisive factor here is the hard material group used in accordance with DIN 1100 (A, M, KS).

Typical hard material groups and achievable wear classes:

| Hard material group (DIN 1100) | Type. Wear class (A value) | Suitability for stress |

|---|---|---|

| A (Mineral hard materials) | A9, A6, A3 | Medium to high load (warehouse, workshop) |

| M (Metallic hard materials) | A3 | Very high load, impact load, heavy load |

| KS (corundum/silicon carbide) | A1,5 | Extremely high grinding loads (e.g. steel roller traffic) |

ℹ️ Important: The selection of the correct screed class and hard material group is crucial and should be based on a precise analysis of the expected load by specialist planners or experienced screed layers.

Processing & laying hard aggregate screed

The quality stands and falls with professional installation. Usual methods for working with hard aggregate screed:

- Single-layer bonded screed: Application of the "fresh-on-fresh" hard aggregate dry mortar to the prepared base concrete or to hardened concrete with bonding bridge.

- Two-layer structure: On separating or insulating layer, consisting of sub screed and hard aggregate layer.

- Hard aggregate scattering (dry shake): Uniform scattering of hard aggregates on the fresh sub-concrete/screed and mechanical incorporation.

Decisive steps for quality:

- Surface preparation: Clean, stable and, if necessary, roughened (e.g. shot blasting) surface.

- Precise mixing: Compliance with the manufacturer's specifications, in particular the water/cement ratio.

- Careful installation & compaction: guaranteeing the nominal thickness and a dense structure.

- Professional surface finish: machine smoothing for high evenness in accordance with DIN 18202 and a sealed surface.

- Essential post-treatment: Protection from drying out too quickly(screed post-treatment) is essential for strength development and to prevent cracks.

We carry out the professional laying of hard aggregate screed and guarantee the highest quality of workmanship.

Your expert for hard aggregate screed

A heavy-duty industrial floor is a long-term investment. Place your trust in our expertise and our quality promise:

- Standard-compliant design: Consistent compliance with all relevant standards (DIN 18560-7, DIN EN 13813, DIN 1100, DIN 18202).

- Certified materials: Use of high-quality, tested hard materials and binders.

- Professional expertise & experience: Our specialist screed layers have mastered the demanding technique of laying hard screed.

- Maximum precision: We guarantee the required evenness for optimum usability.

- Care & reliability: We work with the utmost care, from substrate testing to final finishing.

- Transparent advice: We provide you with comprehensive advice on the optimum solution for your specific requirements.

Choose a durable, wear-resistant hard aggregate screed from a specialist - for a floor that delivers what it promises.

Frequently asked questions (FAQ)

Hard aggregate screed contains extremely hard aggregate grains (hard aggregates) in its top layer (wear layer). These make the surface significantly harder and more abrasion-resistant than that of a normal screed, which only has sand/gravel as aggregate.

No. In the conventional infill method, the hard aggregate infill is worked into the fresh sub screed or concrete and forms a monolithic, inseparable unit with it. It is not a separate layer that is applied subsequently.

Due to its high density, it is more resistant to the penetration of liquids (e.g. oils) than normal concrete/screed. However, it does not offer comprehensive chemical resistance like special synthetic resin systems (SR). An additional coating is often required for heavy chemical exposure.

Yes, the hard aggregates are available in various standard colors (often shades of gray, but also red, green, etc.), giving the finished floor a continuous color.

It is relatively easy to clean. Regular sweeping or mechanical wet cleaning with suitable neutral or slightly alkaline cleaners is usually sufficient. Depending on the wear and tear, periodic refreshing of any impregnation or sealing may be advisable.